1959 Oliver 550 throttle linkage diagram sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail with betawi humor style and brimming with originality from the outset. The Oliver 550, a workhorse of the farm, relied on a complex system of levers and cables to control the engine’s speed.

This intricate network, known as the throttle linkage, played a crucial role in the tractor’s performance. Imagine trying to drive a car without a gas pedal – that’s what it’d be like for the Oliver 550 without its throttle linkage!

This guide dives into the inner workings of this vital system, exploring its components, functions, and common problems. We’ll unravel the mysteries of the throttle linkage diagram, helping you understand its purpose and decipher its cryptic symbols. So buckle up, grab your toolbox, and get ready to learn about the throttle linkage – a crucial element in keeping your Oliver 550 running smoothly.

Introduction to the Oliver 550 Tractor

The Oliver 550 tractor, a product of the Oliver Corporation, was a popular and reliable workhorse in the agricultural industry during the late 1950s and early 1960s. Its sturdy construction, powerful engine, and versatility made it a favorite among farmers across the United States.The Oliver 550 tractor was a testament to the company’s commitment to producing durable and efficient farm machinery.

It was designed to handle a wide range of tasks, from plowing and disking to planting and harvesting.

Key Features and Specifications

The Oliver 550 tractor boasted several key features that contributed to its success. These included:

- A powerful 4-cylinder gasoline engine that delivered ample power for various agricultural operations.

- A robust transmission system that provided smooth and reliable gear changes.

- A hydraulic system that facilitated the operation of various implements.

- A comfortable operator’s station with clear visibility and easy-to-use controls.

The Oliver 550 tractor was available in various configurations, each tailored to specific needs. The standard model featured a 3-point hitch, while others included a front-end loader or a PTO (power take-off) for powering additional implements.

Importance of the Throttle Linkage

The throttle linkage plays a crucial role in the operation of the Oliver 550 tractor. It connects the throttle control lever in the operator’s station to the engine’s carburetor, allowing the operator to adjust the engine speed.

The throttle linkage is responsible for controlling the amount of fuel delivered to the engine, which directly affects the engine’s power output and speed.

A properly functioning throttle linkage ensures that the engine responds smoothly to the operator’s commands, enabling efficient and safe operation of the tractor.

Components of the Throttle Linkage

The throttle linkage system in the Oliver 550 tractor is crucial for controlling the engine speed, which in turn determines the tractor’s power output. This system allows the operator to precisely adjust the engine’s speed, ensuring efficient operation for various tasks.

Components of the Throttle Linkage System

This section Artikels the key components of the throttle linkage system and their functions:

| Component | Description | Function |

|---|---|---|

| Throttle Lever | The throttle lever is a hand-operated control located on the steering column. It is usually a lever that is moved forward to increase engine speed and backward to decrease engine speed. | The throttle lever acts as the primary control for the operator to adjust the engine speed. When the lever is moved, it actuates the linkage system, ultimately controlling the fuel flow to the engine. |

| Throttle Cable | The throttle cable is a flexible cable that connects the throttle lever to the throttle arm. It is typically made of steel wire encased in a protective sheath. | The throttle cable transmits the movement of the throttle lever to the throttle arm, effectively connecting the operator’s input to the engine’s fuel control mechanism. |

| Throttle Arm | The throttle arm is a lever attached to the engine’s governor assembly. It is typically a metal arm that pivots around a fixed point. | The throttle arm receives movement from the throttle cable and directly controls the position of the governor assembly. The governor assembly regulates the engine speed by adjusting the fuel flow. |

| Governor Assembly | The governor assembly is a mechanical device that regulates the engine speed. It consists of various components, including a centrifugal governor, a linkage system, and a fuel control mechanism. | The governor assembly maintains a consistent engine speed by adjusting the fuel flow to the engine based on the throttle arm position and the engine’s rotational speed. |

Operating Principles of the Throttle Linkage

The throttle linkage system on the Oliver 550 tractor plays a crucial role in controlling the engine’s speed. It acts as a mechanical connection between the throttle lever, which is operated by the driver, and the carburetor, which regulates the amount of fuel entering the engine.

By adjusting the throttle lever, the driver can alter the engine’s speed to match the demands of the work being done.

Throttle Linkage System Function

The throttle linkage system works by manipulating the position of the throttle valve within the carburetor. When the throttle lever is moved, the linkage components transmit this movement to the throttle valve. This change in valve position directly affects the amount of air that enters the carburetor, and consequently, the amount of fuel that is mixed with the air.

- Throttle Lever:The throttle lever, located on the tractor’s dashboard, is the primary control for adjusting engine speed. It is connected to the throttle linkage through a cable or rod.

- Throttle Linkage Components:These components, including rods, levers, and cables, transmit the movement from the throttle lever to the throttle valve. They are designed to ensure smooth and accurate control over engine speed.

- Throttle Valve:This valve, located within the carburetor, regulates the amount of air that enters the carburetor. When the throttle lever is moved, the throttle valve opens or closes, allowing more or less air to enter the carburetor, thus controlling the fuel-air mixture and ultimately the engine’s speed.

Common Problems with the Throttle Linkage

The throttle linkage system on an Oliver 550 tractor, while generally robust, can experience issues over time due to wear and tear, environmental factors, or improper maintenance. Understanding these common problems and their causes is crucial for efficient troubleshooting and repair.

Causes of Throttle Linkage Problems

The throttle linkage system on an Oliver 550 tractor is prone to several issues, each with its own set of contributing factors. Understanding these causes can help you pinpoint the source of the problem and effectively address it.

- Wear and Tear:The throttle linkage components, including the cables, levers, and rods, are subjected to constant movement and stress during operation. Over time, this wear can lead to frayed cables, worn-out bearings, or loose connections.

- Corrosion:Exposure to moisture, dirt, and other environmental elements can lead to corrosion of metal components, particularly in the throttle linkage system. This corrosion can hinder smooth movement, causing the linkage to stick or bind.

- Improper Adjustment:Incorrect adjustment of the throttle linkage can result in sluggish engine response or an inability to reach full throttle. This often occurs when the linkage is adjusted without proper tools or expertise.

- Damaged Components:Accidents, mishandling, or improper maintenance can cause damage to components within the throttle linkage system. This includes bent levers, broken cables, or worn-out springs.

Troubleshooting Throttle Linkage Issues

When encountering problems with the throttle linkage system, it’s essential to systematically troubleshoot the issue to identify the root cause. Here’s a step-by-step approach:

- Visual Inspection:Begin by carefully inspecting the entire throttle linkage system. Look for any signs of wear, corrosion, damage, or loose connections.

- Cable Movement:Check the throttle cable for smooth movement. If it’s sticking or binding, there might be a problem with the cable itself or the cable guide.

- Lever Movement:Inspect the throttle lever and its connection points. Ensure it moves freely and smoothly.

- Engine Response:Test the engine response by adjusting the throttle lever. If the engine doesn’t respond smoothly or doesn’t reach full throttle, there’s likely a problem with the linkage.

- Adjustment:If the throttle linkage is out of adjustment, carefully adjust it according to the manufacturer’s specifications. Use appropriate tools and avoid overtightening any connections.

Common Problems and Solutions

- Sluggish Engine Response:This is often caused by a worn or frayed throttle cable, a binding linkage, or an incorrect adjustment.

- Solution:Replace the throttle cable if it’s worn or frayed. Inspect the linkage for binding and lubricate any moving parts. Adjust the throttle linkage according to the manufacturer’s specifications.

- Engine Won’t Reach Full Throttle:This can be caused by a broken throttle cable, a stuck throttle lever, or a damaged throttle linkage component.

- Solution:Replace the throttle cable if it’s broken. Free the stuck throttle lever by cleaning and lubricating the linkage. Inspect the linkage for damaged components and replace them as needed.

- Throttle Stick:This issue often occurs due to corrosion, dirt buildup, or worn-out bearings in the throttle linkage.

- Solution:Clean and lubricate the throttle linkage thoroughly. Replace any worn-out bearings.

Repair and Maintenance of the Throttle Linkage

The throttle linkage on your Oliver 550 tractor is a vital component for controlling engine speed. Over time, this linkage can become worn, damaged, or misaligned, leading to inconsistent engine performance and potential issues. To ensure optimal operation and prevent future problems, regular inspection, maintenance, and repair are crucial.

Inspecting and Maintaining the Throttle Linkage

The throttle linkage is a mechanical system that requires regular inspection and maintenance to ensure proper operation.

- Check for wear and tear:Inspect the throttle cable, linkage rods, and pivot points for signs of wear, such as fraying, corrosion, or excessive play.

- Lubricate moving parts:Apply a light lubricant to the throttle cable, linkage rods, and pivot points to reduce friction and wear.

- Adjust linkage tension:Ensure the throttle cable is properly tensioned so that the throttle lever moves smoothly and returns to its idle position without excessive play.

- Check for binding:Ensure the throttle linkage moves freely without any binding or resistance.

- Inspect the throttle lever:Ensure the throttle lever is securely attached to the linkage and moves smoothly without any play.

Replacing Worn or Damaged Components

If you find any worn or damaged components in the throttle linkage, you will need to replace them to restore proper operation.

- Identify the damaged component:Determine which part of the linkage needs to be replaced, such as the throttle cable, linkage rods, or pivot points.

- Order replacement parts:Obtain the correct replacement parts from a reputable supplier.

- Disconnect the linkage:Disconnect the throttle cable from the throttle lever and the carburetor.

- Remove the damaged component:Remove the damaged component from the linkage.

- Install the new component:Install the new component, ensuring it is properly secured and aligned.

- Reconnect the linkage:Reconnect the throttle cable to the throttle lever and the carburetor.

- Adjust the linkage:Adjust the throttle cable tension and ensure the throttle lever moves smoothly and returns to its idle position without excessive play.

Preventative Maintenance Practices

To prevent premature wear and tear on the throttle linkage, consider implementing these preventative maintenance practices:

- Regularly inspect the linkage:Check for wear and tear at least once a month, or more frequently if the tractor is used extensively.

- Lubricate moving parts:Apply a light lubricant to the throttle cable, linkage rods, and pivot points at least once a month.

- Avoid excessive force:Do not apply excessive force to the throttle lever, as this can damage the linkage.

- Store the tractor properly:When not in use, store the tractor in a dry, clean environment to prevent corrosion and damage to the linkage.

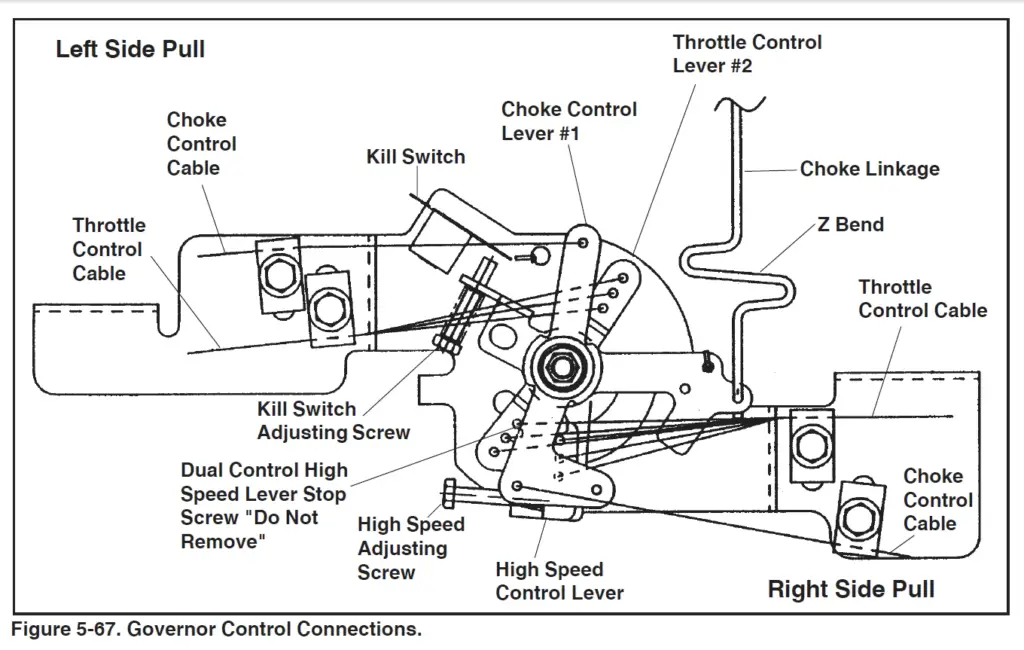

Understanding the Throttle Linkage Diagram

The throttle linkage diagram is a crucial tool for understanding the intricate workings of the Oliver 550 tractor’s engine speed control system. It provides a visual representation of the various components and their interconnections, allowing for effective troubleshooting and maintenance.

Symbols and Notations, 1959 oliver 550 throttle linkage diagram

The diagram employs specific symbols and notations to represent different parts and their functionalities. These symbols help in visualizing the flow of motion and the relationship between components.

Understanding the intricate workings of a 1959 Oliver 550 throttle linkage diagram requires a deep dive into its mechanical components. While this may seem unrelated, the concept of a well-functioning system applies to other areas, like the black water system 5th wheel keystone rv plumbing diagram , where proper plumbing is essential for a comfortable RV experience.

Just as the throttle linkage ensures smooth engine operation, a properly designed black water system ensures efficient waste removal. Returning to the 1959 Oliver 550, a thorough understanding of its throttle linkage diagram is key to maintaining its optimal performance.

- Lines:Solid lines represent physical connections, while dashed lines indicate electrical connections.

- Arrows:Arrows indicate the direction of movement or flow.

- Labels:Each component is labeled with its specific name or function.

Diagram Layout and Information

The diagram is typically arranged in a logical manner, often with the throttle lever at the top and the engine at the bottom. It shows the complete path of the throttle linkage, from the throttle lever to the engine governor.

- Components:The diagram highlights all essential components, including the throttle lever, linkage rods, governor linkage, governor spring, and engine throttle plate.

- Connections:The diagram illustrates how these components are interconnected, including the pivot points, bearings, and adjustments.

- Operation:By studying the diagram, you can understand how the throttle lever’s movement translates into engine speed adjustments through the linkage system.

Safety Considerations for Working on the Throttle Linkage

Working on the throttle linkage of your Oliver 550 tractor requires careful attention to safety. Neglecting safety precautions can lead to serious injuries, so it’s crucial to prioritize your well-being throughout the process.

Safety Precautions

Before starting any work on the throttle linkage, it’s important to take several safety precautions. This will help minimize the risk of accidents and ensure a safe working environment.

- Disconnect the battery:This prevents the engine from accidentally starting while you’re working on the linkage. Disconnect the negative terminal first to avoid sparks.

- Chock the wheels:Before you begin working, make sure to chock the wheels to prevent the tractor from rolling.

- Wear appropriate clothing:Avoid loose clothing that could get caught in moving parts. Wear close-fitting clothes and sturdy footwear.

- Use safety glasses:Protect your eyes from flying debris or engine fluids.

- Work in a well-lit area:Ensure you have adequate lighting to see clearly what you’re doing.

Identifying and Mitigating Potential Hazards

The throttle linkage system is a complex network of components, and there are certain potential hazards that you need to be aware of.

- Moving parts:The throttle linkage has several moving parts that can cause injury if not handled carefully. Always be aware of the location of these parts and avoid touching them while the engine is running.

- Engine fluids:The engine can leak fluids like oil, coolant, and fuel, which can be slippery and cause falls. Wear gloves and work in a well-ventilated area to avoid inhaling fumes.

- Sharp edges:The throttle linkage components can have sharp edges that can cause cuts. Be careful when handling these parts and wear gloves if necessary.

Working Safely with the Throttle Linkage

Following these safety guidelines will help you avoid accidents and ensure a safe working environment:

- Never work on the throttle linkage while the engine is running:This is crucial for preventing serious injuries from moving parts.

- Use caution when working around the engine:Be aware of hot surfaces and moving parts.

- Always use proper tools and equipment:This ensures that you have the right tools for the job and that you are using them safely.

- Take breaks if you feel tired:Fatigue can lead to mistakes and accidents. Take regular breaks to stay alert and focused.

- If you are unsure about anything, consult a qualified mechanic:This will ensure that you are working safely and correctly.

Resources for Further Information: 1959 Oliver 550 Throttle Linkage Diagram

There are several resources available to help you learn more about the Oliver 550 throttle linkage. These resources can provide detailed information, troubleshooting tips, and community support.

Online Resources

Online resources can be a valuable source of information for understanding the Oliver 550 throttle linkage. These resources can provide detailed diagrams, repair manuals, and troubleshooting guides.

- Oliver Tractor Parts & Manuals:This website offers a wide selection of parts and manuals for Oliver tractors, including the 550 model. You can find detailed diagrams, repair manuals, and troubleshooting guides for the throttle linkage.

- TractorData.com:This website provides technical specifications and information for a variety of tractors, including the Oliver 550. You can find information on the throttle linkage system, including its components and operating principles.

- YouTube:Search for videos on YouTube related to Oliver 550 throttle linkage repair and maintenance. You can find tutorials and demonstrations on how to diagnose and fix common problems.

Publications and Manuals

Published manuals and documents can provide in-depth information about the Oliver 550 throttle linkage. These resources are often written by experts and provide detailed instructions for repair and maintenance.

- Oliver 550 Operator’s Manual:This manual provides detailed information on operating and maintaining the Oliver 550 tractor, including the throttle linkage system. It includes diagrams, troubleshooting tips, and specifications.

- Oliver 550 Parts Catalog:This catalog lists all the parts for the Oliver 550 tractor, including the throttle linkage components. It provides part numbers, descriptions, and diagrams.

- Oliver 550 Service Manual:This manual provides detailed instructions for repairing and maintaining the Oliver 550 tractor, including the throttle linkage system. It includes diagrams, troubleshooting guides, and specifications.

Forums and Communities

Connecting with other Oliver 550 owners and enthusiasts can be a valuable resource for seeking assistance and sharing knowledge.

- Oliver Tractor Forums:Several online forums are dedicated to Oliver tractors. These forums are a great place to ask questions, share experiences, and get advice from other owners.

- Antique Tractor Clubs:Local antique tractor clubs often have members who specialize in Oliver tractors. These clubs can provide resources, support, and access to experts.

Visual Guide to the Throttle Linkage

This section will provide a visual representation of the Oliver 550 throttle linkage system, highlighting the key components and their functions. Understanding the visual guide is crucial for troubleshooting and maintenance tasks.

Detailed Illustration of the Throttle Linkage System

The throttle linkage system in an Oliver 550 tractor is responsible for regulating the engine speed by controlling the amount of fuel entering the combustion chamber. The system consists of several interconnected components that work in unison. Here is a detailed illustration:  The illustration shows the throttle linkage system, with each component labeled for clarity.

The illustration shows the throttle linkage system, with each component labeled for clarity.

The system starts with the throttle lever, which is operated by the operator. This lever is connected to a throttle cable, which runs to the governor. The governor is a mechanical device that regulates the engine speed by controlling the fuel flow.

The governor is connected to the throttle linkage, which consists of several rods and levers that transmit the motion from the throttle lever to the governor. The throttle linkage is also connected to the fuel pump, which supplies fuel to the engine.

The throttle linkage system is a critical component of the Oliver 550 tractor. It allows the operator to control the engine speed and ensures smooth operation of the tractor.

Case Studies and Troubleshooting Examples

The throttle linkage on your Oliver 550 tractor can be a bit of a pain sometimes, especially when it decides to act up. But don’t worry, we’re here to help you tackle those tricky situations. Here are some real-world examples of common problems and how to fix them.

Throttle Linkage Not Responding

A common issue is the throttle linkage not responding properly. This can be caused by a few things, like a worn-out cable, a stuck throttle lever, or a loose connection. To troubleshoot this, you’ll need to inspect the entire linkage system.

Check the cable for fraying or kinks, and make sure the throttle lever moves freely. If you find a problem, replace the worn-out parts or tighten the loose connections.

Engine Speed Fluctuates

If your engine speed is fluctuating, it might be due to a problem with the throttle linkage. This could be caused by a faulty governor, a loose throttle cable, or a worn-out throttle shaft. To fix this, start by checking the governor.

If it’s not working properly, you’ll need to adjust or replace it. If the throttle cable is loose, tighten it. And if the throttle shaft is worn, you’ll need to replace it.

Engine Won’t Idle

If your engine won’t idle properly, it might be due to a problem with the throttle linkage. This could be caused by a stuck throttle lever, a faulty throttle cable, or a clogged air filter.To troubleshoot this, check the throttle lever to see if it’s stuck.

If it is, you’ll need to free it up. If the throttle cable is faulty, you’ll need to replace it. And if the air filter is clogged, you’ll need to clean or replace it.

Query Resolution

What’s the difference between a throttle linkage and a carburetor?

The throttle linkage is the system of levers and cables that connect the throttle lever to the carburetor. The carburetor itself is the device that mixes air and fuel for the engine. Think of the throttle linkage as the messenger, delivering the instructions from the throttle lever to the carburetor.

How often should I inspect the throttle linkage?

It’s best to check the throttle linkage regularly, especially after heavy use or if you notice any issues with engine performance. A good rule of thumb is to inspect it every 50 hours of operation or at least once a year.

What should I do if I find a broken throttle linkage component?

Don’t try to fix a broken component yourself. It’s best to replace it with a new one. If you’re not sure what to do, consult a mechanic.

What are some common signs of a faulty throttle linkage?

Some signs include the engine not accelerating smoothly, the throttle lever not responding properly, or the engine stalling.